Open Dependability: How Top Quality Komatsu Undercarriage Parts Can Enhance Procedures

Open Dependability: How Top Quality Komatsu Undercarriage Parts Can Enhance Procedures

Blog Article

Effective Solutions: Undercarriage Parts for Heavy Machinery

Quality undercarriage components play a considerable role in making sure the smooth procedure and durability of heavy machinery. In this conversation, we will certainly discover the importance of spending in first-class undercarriage components, common wear difficulties dealt with by hefty equipment drivers, the benefits of timely substitutes, standards for picking dependable vendors, and essential maintenance suggestions to prolong the life expectancy of undercarriage parts.

Importance of Quality Undercarriage Parts

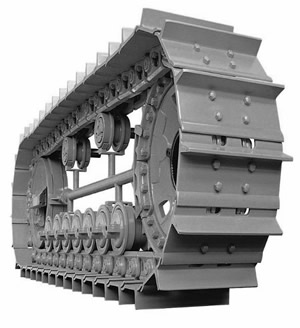

Quality undercarriage parts are vital elements in making certain the durability and performance of heavy machinery. The undercarriage of equipment such as excavators, bulldozers, and track loaders plays a crucial role in supporting the maker's weight, supplying security on different surfaces, and taking in the effect of unequal surfaces. By investing in top quality undercarriage parts, operators can significantly expand the life-span of their equipment and minimize the danger of unforeseen break downs.

One key benefit of making use of top quality undercarriage parts is the enhancement of overall machine efficiency. Long lasting tracks, rollers, idlers, and sprockets minimize friction and make certain smoother motion, eventually leading to increased productivity and efficiency on work websites. Dependable undercarriage parts lessen downtime for maintenance and fixings, enabling operators to optimize their operational hours and job deadlines.

Typical Undercarriage Wear Concerns

Advantages of Timely Replacement

One key benefit of timely undercarriage part substitute is increased maker uptime. By changing used components before they fail, the threat of unforeseen malfunctions is decreased, decreasing downtime for repairs and upkeep. This aggressive technique not only keeps the heavy machinery operational however likewise prevents prospective damage to other parts that could arise from a falling short undercarriage.

Furthermore, changing undercarriage parts immediately can enhance total performance. A properly maintained undercarriage guarantees optimum equipment efficiency, enabling smoother operation and higher effectiveness in finishing jobs. This, consequently, causes increased work website productivity and expense savings by staying clear of hold-ups and disruptions brought on by underperforming machinery. For that reason, buying timely undercarriage component replacement is a proactive approach that settles in terms of improved performance and reduced functional prices.

Picking the Right Undercarriage Supplier

Picking the proper undercarriage distributor is an important choice that considerably influences the performance and upkeep of heavy equipment. When selecting a supplier for undercarriage components, numerous factors must be taken into consideration to guarantee optimum effectiveness and cost-effectiveness. A distributor that offers a broad option of undercarriage parts for various hefty machinery brands and designs can be useful as it gives more alternatives to satisfy certain requirements.

In addition, evaluating the distributor's consumer solution and support is essential. A provider that supplies superb client this post service, fast feedback times, and technological assistance can assist minimize downtime and make certain smooth procedures. Price is also a considerable variable to take into consideration; nonetheless, it needs to not be the single component. Stabilizing cost-effectiveness, dependability, and quality is essential when choosing the best undercarriage vendor for heavy machinery. By meticulously evaluating these factors, you can choose a supplier that meets your requirements and adds to the efficient performance and upkeep of your hefty equipment.

Maintenance Tips for Extended Life-span

To make sure a prolonged lifespan for hefty machinery undercarriage components, carrying out a proactive upkeep routine is important. Routinely inspecting undercarriage parts such as track chains, idlers, rollers, and sprockets for damage is vital. Any indicators of damage or too read here much wear must be promptly resolved to stop more degeneration and potential failings. Additionally, maintaining the undercarriage clean from dirt, particles, and destructive products can considerably lengthen its lifespan. Oiling relocating parts according to supplier recommendations helps in reducing friction and protect against premature wear. Checking track tension and positioning is also crucial to protect against unequal endure the undercarriage parts. Buying high quality undercarriage components from trustworthy providers is just as important for guaranteeing durability. By adhering to these maintenance suggestions carefully, hefty equipment owners can enhance a knockout post the performance and longevity of their undercarriage parts, ultimately minimizing downtime and functional prices.

Final Thought

In conclusion, top quality undercarriage parts are important for the reliable operation of hefty machinery. Choosing a trusted provider and following appropriate maintenance methods are key to making certain the prolonged life-span of undercarriage elements.

Too much wear and tear on undercarriage components of heavy machinery can lead to substantial functional difficulties and enhanced maintenance prices. Routine evaluations, proper maintenance, and timely replacements of used undercarriage parts are vital to mitigate these usual wear issues and guarantee the optimum performance of heavy equipment.

A provider that offers a broad option of undercarriage components for numerous heavy equipment brands and models can be useful as it offers more alternatives to meet details requirements.

By following these upkeep tips faithfully, heavy equipment owners can maximize the performance and durability of their undercarriage components, ultimately minimizing downtime and operational expenses.

Report this page